Two Bin Kanban System

Two bin kanban system. A melhor ferramenta de Kanban em português e gratuita. Bins are placed front-to-back. A two-bin Kanban system aids in lean manufacturing practices to reduce costs and waste in a number of.

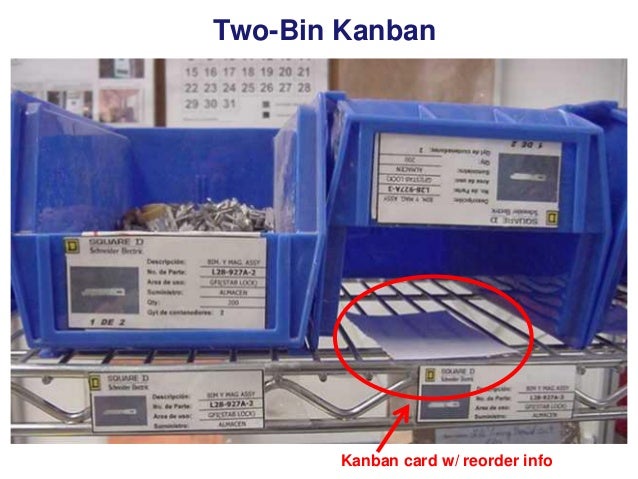

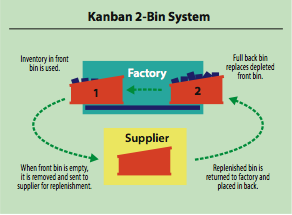

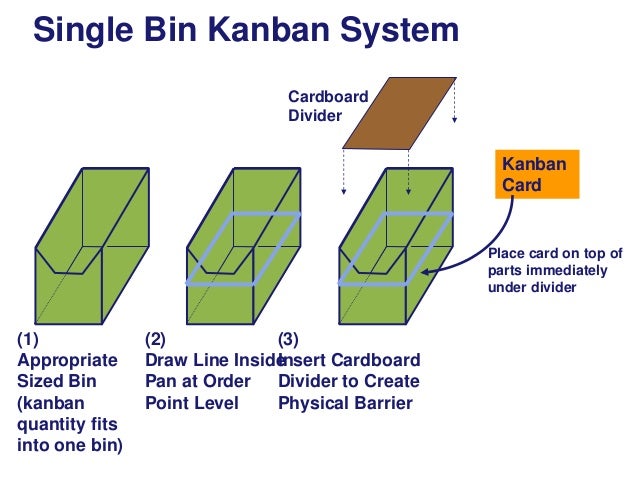

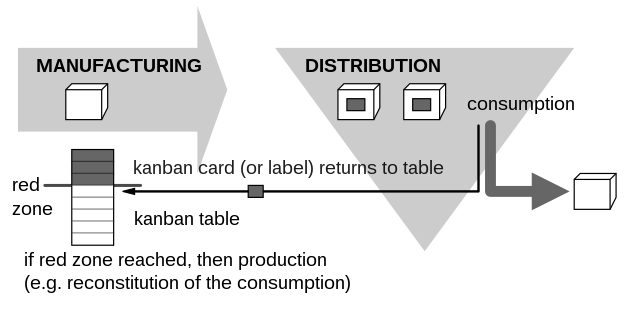

Others have Americanized the TPS and made it more culturally accessible in the United States and other countries. Video explanation of two bin Kanbans. A two-bin system is mathematically equivalent to a single kanban card following the rule of sending the card back when the first part is pulled from the container.

Ad Solução completa para organizar e aumentar a produtividade da sua empresa. If the math doesnt work for one card then two bins wont work either. Kanban is a methodology in lean manufacturing which manages and improves workload within production.

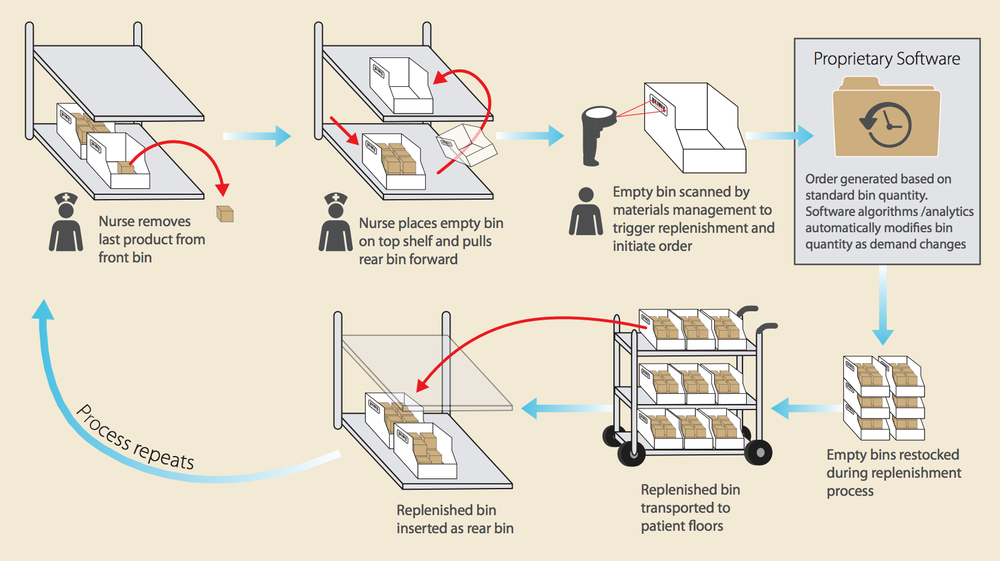

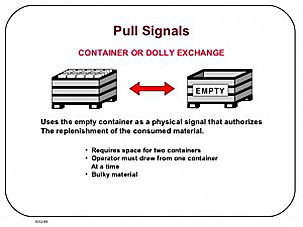

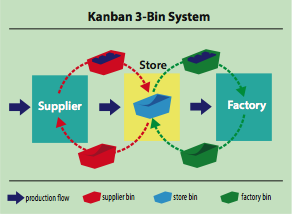

Items are picked from the first bin and when empty it is placed on the top shelf to be refilled. Kanban signals and maintain an inventory level. Kanban cards are sent to produce and deliver new shipment as the material is consumed.

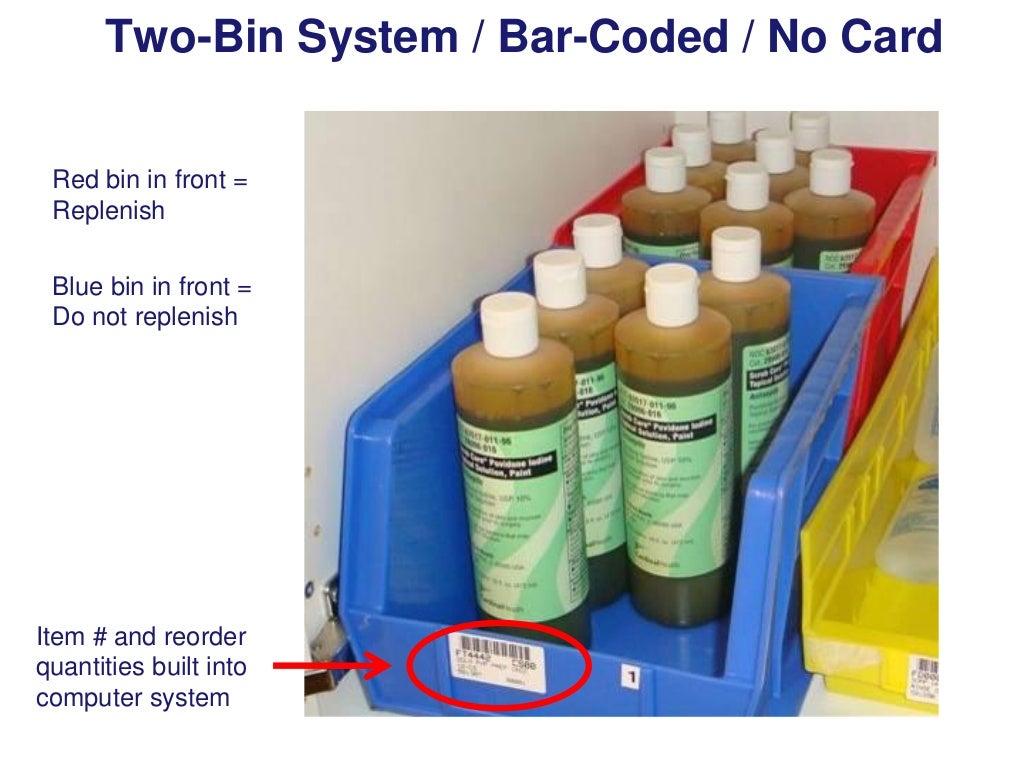

2SS11424 The Cardinal Health 2-Bin Kanban solution combines lean management techniques with proprietary cloud-based software that learns from your consumption patterns in real-time calculating correct bin quantities as changes in. The two bins system workes best when criterias are met which makes it more efficient. One of the most familiar tools used in Kanban manufacturing is called a 2 bin.

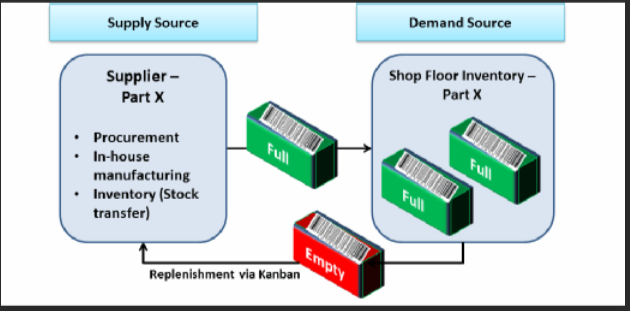

The two-bin inventory control method is also sometimes referred to as kanban which is strongly associated with the just-in-time JIT method of a manufacturing process. St Clair is a large community hospital just outside Pittsburgh PA that has committed to using ToyotaLean principles and methods for continuous improvement. How It Works The system works simply by supplying two plastic bins to workers which contain inventory that they pull from to fill orders or to provide supplies to various departments.

Evolution of the Two-Bin Kanban Method. A two-bin system is the easiest way to implement a kanban system into a manufacturing or production facility.

Please see below our guide to implementing a simple two-bin system.

Items are picked from the first bin and when empty it is placed on the top shelf to be refilled. Unlock the potential of your team with Jira Software today. The two-bin inventory control method is also sometimes referred to as kanban which is strongly associated with the just-in-time JIT method of a manufacturing process. For those that work in factories two containers are made available just for inventory. Two bins with materials are placed on the factory floor. How does the Two-Bin system work. A melhor ferramenta de Kanban em português e gratuita. Ad Solução completa para organizar e aumentar a produtividade da sua empresa. Unlock the potential of your team with Jira Software today.

For those that work in factories two containers are made available just for inventory. Video explanation of two bin Kanbans. Kanban cards are sent to produce and deliver new shipment as the material is consumed. Here as discussed the 2 bins system is based on the visual signal to replacement of the bin. Some are closely aligned with the Toyota Production System TPS and tend to use a lot of Japanese terms and concepts. Two bins with materials are placed on the factory floor. Two-bin kanban involves two bins with identical quantities.

Post a Comment for "Two Bin Kanban System"